Forging and casting are two distinct metalworking processes, with significant differences in their principles, processes, applicable materials, and product performance. The following detailed comparison of the two differences covers multiple dimensions:

1. Core Differences in Process Principles

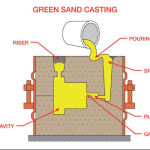

Ø Casting: Melting → Pouring → Solidification → Demolding. Metal (mostly alloys) is heated to a liquid state, then poured into a prefabricated mold (sand mold, metal mold, etc.). The desired shape is obtained after cooling and solidification. This core concept is “liquid forming,” relying on the metal’s fluidity to fill the mold.

Ø Forging: Heating (optional) → Pressure Deformation → Forming. While the metal is in a solid state (possibly heated to a plastic state but not melted), it is plastically deformed by external forces (such as hammering or extrusion) to produce a workpiece with a specific shape and properties. This core concept is “solid-state plastic deformation,” relying on the metal’s forgeability.

2. Applicable Materials and Product Scenarios

Ø Casting: Applicable Materials: Metals with good fluidity, such as cast iron, cast steel, aluminum alloys, and copper alloys (especially suitable for complex shapes and difficult-to-forge materials).

Typical Products: Parts with complex shapes and uneven wall thicknesses, such as engine blocks, machine tool beds, pipe elbows, and artwork castings.

Ø Forging: Applicable Materials: Metals with good plasticity, such as carbon steel, alloy steel, copper, and aluminum (brittle materials such as gray cast iron cannot be forged).

Typical Products: Parts requiring high strength and toughness, such as gears, crankshafts, connecting rods, wrenches, and tool blanks.

3. Product Performance Differences

Ø Castings:

May contain internal defects such as pores and pinholes, resulting in lower density.

Mechanical properties may be inferior (e.g., lower strength and toughness than forgings), but vibration damping is better (e.g., cast iron machine tool beds can reduce vibration).

Ø Forgings:

After plastic deformation, metals undergo internal grain refinement, resulting in a dense structure and fewer defects.

They possess excellent mechanical properties (significantly higher strength, hardness, and toughness than castings), and continuous metal fiber flow lines (distributed along the direction of force), resulting in strong fatigue resistance.

4. Other Key Differences

l Cost: Casting is suitable for mass production of complex parts, with lower mold costs (e.g., sand casting). Forging equipment investment is high (e.g., large presses), but material utilization is higher (less or no cutting).

l Shape Complexity: Casting can produce more complex shapes (e.g., cavities and curved surfaces), while forging is limited by plastic deformation and results in relatively simpler shapes (complex shapes require multiple steps).

l Surface Quality: Castings may have a rough surface (requiring subsequent machining), while forgings have a smoother surface and require less machining allowance.

Summary

Casting is a “liquid forming” process, excelling at complex shapes but with limited performance. Forging is a “solid deformation” process, focusing on high performance but with limited shape requirements. Each process has its advantages. In actual production, the appropriate process should be selected based on the part’s performance requirements, shape complexity, and material properties.