Investment casting, due to its high precision and ability to form complex shapes, is widely used in many fields with stringent quality requirements for castings.

u Aerospace:

Used to manufacture critical engine components, such as turbine blades, guide vanes, and combustion chambers.

Suitable for difficult-to-machine materials such as high-temperature alloys and titanium alloys, meeting the precision and high-temperature resistance requirements of aerospace parts.

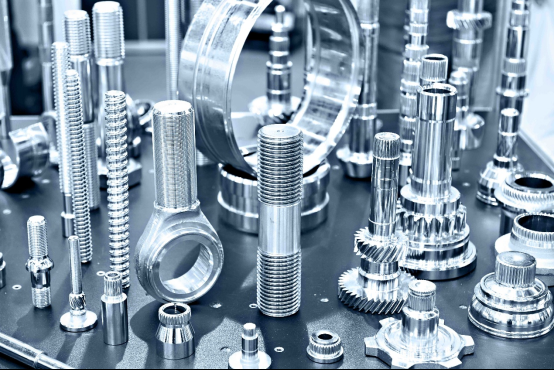

u Machinery Manufacturing:

Produces complex mechanical parts such as gears, turbines, cams, and crankshafts.

Suitable for machine tools, general machinery, and engineering machinery, reducing subsequent machining of parts.

u Automotive Industry:

Manufactures intake and exhaust manifolds, turbocharger components, and gearbox gears for automotive engines.

Balancing mass production needs with part precision, contributing to lightweighting and performance improvements in automobiles.

u Medical Devices:

Produces surgical instruments, orthopedic implants (such as artificial joints and bone plates), and precision components for medical equipment.

Meets stringent standards for biocompatibility, dimensional accuracy, and surface finish in medical devices.

u Weaponry Industry:

Manufactures gun parts, artillery shell components, and missile engine assemblies.

Adaptable to high-strength alloy materials, ensuring the reliability and tactical performance of weaponry and equipment.

u Other Fields:

Electronics Industry: Production of small, high-precision parts such as precision instrument housings and connectors.

Valves and Fittings: Manufacturing complex valve cores, valve bodies, and pipe fittings, adapted to corrosion-resistant alloys.

Dongpei Invest Casting Process Factory: Prominent Process Advantages Empower Precision Manufacturing in Multiple Fields

Dongpei Customized Invest Casting Process, leveraging its core process advantages and digital innovation, provides high-quality casting solutions for the above fields.

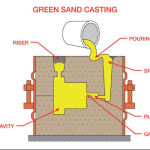

Compared to traditional casting, investment casting can form without molds, accurately reproducing complex internal cavities and fine textures, achieving dimensional accuracy of 5-7 levels and surface roughness as low as Ra6.3μm, eliminating the need for secondary grinding. Its wide material adaptability allows processing of alloy steel, heat-resistant alloys, titanium alloys, and other special materials, with a material utilization rate exceeding 80%, significantly reducing raw material waste and processing costs. Combined with silica sol shell fabrication technology and end-to-end digital quality control, the defect rate is significantly lower than the industry average. It also flexibly meets the needs of both small-batch customization and large-scale mass production, shortening the delivery cycle by more than 20%.

Dongpei Invest Casting Process Suppliers China leverages its strong technological capabilities to overcome the pain points of precision manufacturing, becoming the preferred partner for high-end castings across various industries.