CNC machining removes material through precise cutting, excelling at producing parts with high precision, complex shapes, or small batches:

1. Parts requiring high dimensional accuracy and surface quality

CNC machining can achieve accuracies up to 0.001mm, making it suitable for parts with stringent mating requirements:

l Precision gears (tooth profile accuracy is required to ensure smooth transmission);

l Bearing rings (high coaxiality between the inner and outer diameters is required);

l Hydraulic valve spools (low surface roughness ensures sealing performance);

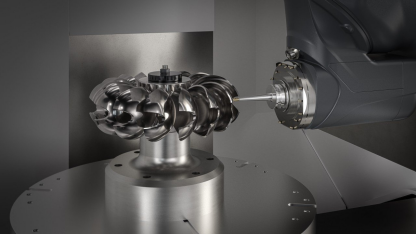

2. Parts with complex but regular shapes

Using CAD/CAM Software and CNC machine tools can process complex structures with multiple curved surfaces and steps:

l Mobile phone midframes (multiple planes, rounded corners, and strict dimensional tolerances);

l Aircraft engine blades (three-dimensional curved surfaces, requiring guaranteed aerodynamic performance);

l Mold cavities (complex curved surfaces, requiring high surface smoothness);

3. Customized parts for single-piece or small-batch production

CNC machining eliminates the need for mold making; production begins after programming, making it suitable for personalized needs:

l Specialized connectors for scientific research equipment (small quantities, unique shapes);

l Customized implants for medical devices (machined based on patient anatomy);

l Specialized structural components for art installations (small batches, unique shapes);

4. Parts requiring multi-process machining

CNC machining centers can complete multiple operations, including milling, drilling, and boring, in a single setup, making them suitable for integrated parts:

l Reducer output shafts (requiring machining of external diameters, keyways, threads, etc.);

l Machine tool tables (requiring machining of flat surfaces, T-slots, and locating holes).